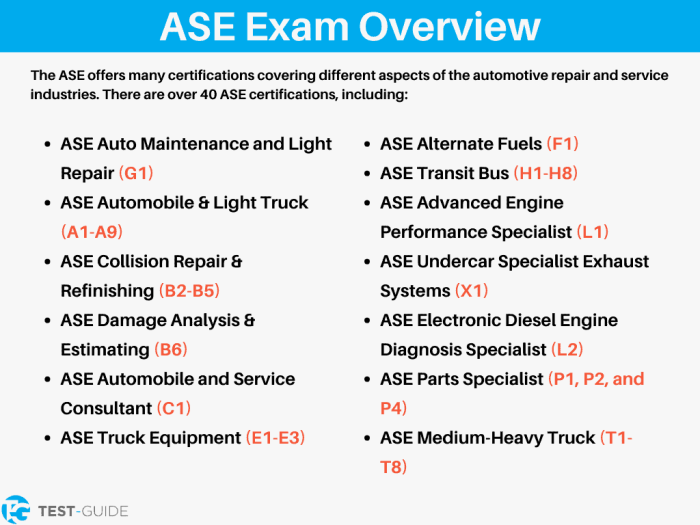

Prepare to excel with the ASE Diesel Engine Practice Test! This comprehensive resource empowers you to delve into the intricate world of diesel engines, equipping you with a profound understanding of their operation, maintenance, and applications. Embark on a journey of knowledge that will transform you into a diesel engine virtuoso.

Delve into the fundamentals of diesel engine operation, unraveling the intricacies of its components and their harmonious interplay. Witness the combustion process unfold, deciphering the role of fuel injection and compression ratio. Discover the maintenance secrets that keep diesel engines running smoothly, empowering you to diagnose and troubleshoot with ease.

Diesel Engine Basics

Diesel engines are internal combustion engines that use compression ignition to burn fuel. They are named after Rudolf Diesel, the German engineer who invented them in 1892. Diesel engines are more efficient than gasoline engines because they burn fuel more completely.

This makes them more economical to operate and produces fewer emissions.The basic principle of diesel engine operation is that air is compressed in a cylinder to a high pressure. This causes the air to heat up. When fuel is injected into the cylinder, it ignites spontaneously because of the high temperature of the air.

The expanding gases from the burning fuel drive the piston down, which in turn rotates the crankshaft.The main components of a diesel engine are the cylinder, piston, crankshaft, connecting rod, valves, fuel injector, and turbocharger. The cylinder is where the combustion takes place.

The piston moves up and down inside the cylinder, compressing the air and driving the crankshaft. The crankshaft converts the up-and-down motion of the piston into rotary motion. The connecting rod connects the piston to the crankshaft. The valves control the flow of air and fuel into and out of the cylinder.

The fuel injector sprays fuel into the cylinder. The turbocharger is used to increase the air pressure in the cylinder, which improves the efficiency of the engine.

The diagram above shows the major parts of a diesel engine. The cylinder is located in the center of the engine. The piston is shown moving up and down inside the cylinder. The crankshaft is located at the bottom of the engine. The connecting rod connects the piston to the crankshaft. The valves are located at the top of the cylinder. The fuel injector is located on the side of the cylinder. The turbocharger is located on the side of the engine.

Diesel Engine Combustion Process

Diesel engines, unlike gasoline engines, rely on compression ignition rather than spark plugs to initiate combustion. The combustion process in a diesel engine occurs over four distinct strokes: intake, compression, power, and exhaust.

Four Strokes of the Diesel Engine Combustion Cycle

- Intake Stroke:The intake valve opens, allowing air to be drawn into the cylinder as the piston moves downward.

- Compression Stroke:Both intake and exhaust valves are closed, and the piston moves upward, compressing the air to a high pressure and temperature.

- Power Stroke:Near the end of the compression stroke, diesel fuel is injected directly into the hot, compressed air. The high temperature causes the fuel to ignite, rapidly expanding and driving the piston downward.

- Exhaust Stroke:The exhaust valve opens, and the piston moves upward, expelling the combustion gases out of the cylinder.

Role of Fuel Injection and Compression Ratio

Fuel injection plays a crucial role in the combustion process. Diesel engines use high-pressure fuel injectors to precisely control the timing, quantity, and atomization of the fuel. This ensures efficient combustion and minimizes emissions.

Compression ratio, which is the ratio of the cylinder volume at the bottom of the compression stroke to the volume at the top, also significantly impacts combustion. A higher compression ratio increases the air temperature and pressure, facilitating easier fuel ignition and more efficient combustion.

Factors Affecting Diesel Engine Efficiency

- Fuel Quality:Higher-quality fuels with higher cetane ratings ignite more easily, improving combustion efficiency.

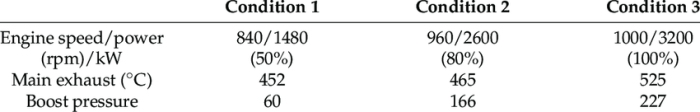

- Engine Speed:Increasing engine speed can reduce combustion efficiency due to shorter time available for fuel-air mixing and combustion.

- Load:Higher loads require more fuel injection, which can impact combustion efficiency if not properly managed.

- Maintenance:Regular maintenance, such as cleaning injectors and checking compression, ensures optimal engine performance and combustion efficiency.

Diesel Engine Maintenance: Ase Diesel Engine Practice Test

Maintaining diesel engines is crucial for optimal performance, longevity, and cost-effectiveness. Adhering to recommended maintenance schedules and performing regular tasks helps prevent breakdowns, minimize repairs, and extend engine lifespan.

Maintenance Schedule

Diesel engine manufacturers typically provide recommended maintenance schedules based on operating hours or mileage. These schedules Artikel specific tasks and intervals for various components, including:

- Oil and filter changes

- Fuel filter replacement

- Air filter cleaning

- Coolant system checks

- Belt and hose inspections

- Valve adjustments

Common Maintenance Tasks

Regular maintenance tasks include:

- Oil and filter changes:Remove old oil and replace with clean oil to lubricate engine components and remove contaminants.

- Fuel filter replacement:Replace the fuel filter to remove dirt and impurities from fuel, preventing injector clogging.

- Air filter cleaning:Clean or replace the air filter to ensure clean air enters the engine, improving combustion and reducing wear.

- Coolant system checks:Inspect coolant levels, hoses, and belts for leaks or damage, and replace or repair as needed.

- Belt and hose inspections:Examine belts and hoses for cracks, wear, or loose connections, and replace if necessary.

- Valve adjustments:Adjust valve clearances to ensure proper engine operation and fuel efficiency.

Troubleshooting and Diagnosing

Diesel engine problems can be diagnosed by observing symptoms and using diagnostic tools. Common issues include:

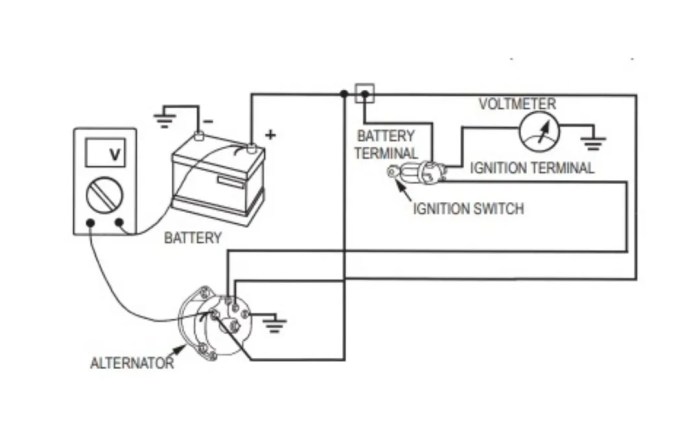

- Hard starting:Check fuel supply, air filter, glow plugs, or battery.

- Rough running:Inspect fuel injectors, air intake system, or compression.

- Excessive smoke:Examine fuel injection system, turbocharger, or air filter.

- Power loss:Check fuel system, turbocharger, or engine compression.

Diesel Engine Emissions

Diesel engines, while efficient and reliable, produce emissions that can have adverse effects on the environment and human health. Understanding the types of emissions, their environmental impact, and the technologies used to reduce them is crucial for responsible engine operation.Diesel

engines primarily emit particulate matter (PM), nitrogen oxides (NOx), and hydrocarbons (HC). PM consists of fine particles that can penetrate deep into the lungs, causing respiratory issues. NOx contributes to smog formation, acid rain, and can aggravate asthma. HC reacts with other pollutants to form ground-level ozone, a major component of smog.

Environmental Impact

Diesel engine emissions have significant environmental consequences. PM and NOx contribute to air pollution, leading to respiratory problems, cardiovascular disease, and premature death. Ozone formed from HC can damage vegetation, reducing crop yields and affecting forest ecosystems. Acid rain, caused by NOx, can harm aquatic life and damage buildings and infrastructure.

Emission Reduction Technologies

To mitigate the environmental impact of diesel engines, various technologies have been developed to reduce emissions. These include:

-

-*Diesel Particulate Filters (DPFs)

Trap and remove PM from exhaust gases.

-*Selective Catalytic Reduction (SCR)

Injects urea into the exhaust to convert NOx into harmless nitrogen and water.

-*Exhaust Gas Recirculation (EGR)

Recirculates a portion of exhaust gases back into the engine to reduce combustion temperatures and NOx formation.

-*Common Rail Fuel Injection

Provides precise fuel delivery and timing, optimizing combustion and reducing emissions.

By implementing these technologies, diesel engines can significantly reduce their environmental footprint, contributing to cleaner air and a healthier planet.

If you’re looking to brush up on your diesel engine knowledge, check out our ASE Diesel Engine Practice Test. It’s a great way to prepare for your ASE certification exam or just to refresh your memory on the basics. Once you’re done, you can take a break and relax with a swim in the pool . Then come back and ace that test!

Diesel Engine Applications

Diesel engines are widely used in various applications due to their high efficiency, reliability, and durability. They are commonly found in:

Automotive Industry

- Trucks and Buses:Diesel engines are the preferred choice for heavy-duty vehicles due to their high torque and fuel efficiency, allowing for efficient transportation of goods and passengers.

- Off-Road Vehicles:Construction equipment, agricultural machinery, and mining vehicles often utilize diesel engines for their robust construction and ability to handle demanding conditions.

- Marine Applications:Diesel engines power boats, ships, and submarines due to their reliability and ability to operate in harsh marine environments.

Industrial Applications

- Generators:Diesel generators provide backup power during power outages or serve as primary power sources in remote areas.

- Industrial Machinery:Diesel engines are used in pumps, compressors, and other industrial equipment due to their high power output and extended operating life.

- Agriculture:Diesel engines are essential for farm machinery, such as tractors, harvesters, and irrigation systems, providing reliable power for agricultural operations.

Advantages of Diesel Engines

- High Efficiency:Diesel engines have a higher thermal efficiency compared to gasoline engines, resulting in lower fuel consumption and operating costs.

- Durability:Diesel engines are known for their rugged construction and longevity, making them suitable for demanding applications.

- High Torque:Diesel engines produce high torque at low RPMs, making them ideal for towing and hauling heavy loads.

- Fuel Availability:Diesel fuel is widely available and relatively inexpensive compared to other fuels.

Disadvantages of Diesel Engines

- Emissions:Diesel engines produce higher emissions, including particulate matter and nitrogen oxides, compared to gasoline engines.

- Noise and Vibration:Diesel engines can be noisy and produce vibrations, especially when operating at low speeds.

- Cold Starting:Diesel engines can be difficult to start in cold weather conditions due to the higher compression ratios.

- Maintenance:Diesel engines require more frequent maintenance compared to gasoline engines due to their complex fuel injection systems.

Diesel Engine Practice Test

This practice test is designed to assess your knowledge of the key concepts of diesel engine operation and maintenance. It covers a wide range of topics, including engine components, fuel systems, lubrication systems, cooling systems, and emissions control. The questions are challenging but fair, and they are designed to help you identify areas where you need additional study.

After you have completed the test, be sure to review the answer key and explanations. This will help you to reinforce your understanding of the material and to identify any areas where you need further clarification.

Questions, Ase diesel engine practice test

- What are the four main components of a diesel engine?

- Describe the function of the fuel injector in a diesel engine.

- What is the purpose of the turbocharger in a diesel engine?

- How does the cooling system in a diesel engine work?

- What are the different types of emissions that are produced by diesel engines?

- How can diesel engine emissions be reduced?

- What are the most common maintenance tasks that need to be performed on diesel engines?

- How often should diesel engines be serviced?

- What are the signs that a diesel engine is in need of repair?

- What are the advantages and disadvantages of diesel engines?

Answer Key

- The four main components of a diesel engine are the cylinder block, cylinder head, crankshaft, and camshaft.

- The fuel injector in a diesel engine is responsible for spraying fuel into the combustion chamber at the correct time and pressure.

- The turbocharger in a diesel engine is used to increase the air pressure in the intake manifold, which results in increased power and efficiency.

- The cooling system in a diesel engine works by circulating coolant through the engine block and cylinder head to remove heat.

- The different types of emissions that are produced by diesel engines include nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

- Diesel engine emissions can be reduced by using a variety of technologies, such as exhaust gas recirculation (EGR), diesel particulate filters (DPFs), and selective catalytic reduction (SCR).

- The most common maintenance tasks that need to be performed on diesel engines include changing the oil and filter, replacing the air filter, and checking the coolant level.

- Diesel engines should be serviced every 3,000 to 5,000 miles, or more frequently if they are used in severe conditions.

- The signs that a diesel engine is in need of repair include excessive smoke, loss of power, and difficulty starting.

- The advantages of diesel engines include their high efficiency, durability, and low fuel consumption. The disadvantages of diesel engines include their higher emissions and noise levels.

Helpful Answers

What is the purpose of the ASE Diesel Engine Practice Test?

To provide a comprehensive review of diesel engine operation, maintenance, and applications, preparing you for the ASE certification exam.

What topics are covered in the practice test?

Diesel engine basics, combustion process, maintenance, emissions, and applications.

Is the practice test challenging?

Yes, it is designed to be challenging but fair, ensuring thorough preparation for the actual exam.